Choosing The Right Sump Pump

Pumps vary widely in quality. Pumps are used in a variety of applications, such as chemical vats, fuel depots, and swimming pools, but each one may present a different set of difficulties. The U.S. Department of Energy suggests the following factors to think about when choosing a pump:

Fluid: Pumps that weren’t designed for the job can be destroyed by chemicals and fuels. Select a pump that is made to handle the fluid’s corrosiveness and consistency to prevent degradation or clogging from slurry or debris. Similar to this, be aware of the fluid’s viscosity to make sure the pump has sufficient force to draw the liquid through.

Calculate the desired flow rate by dividing the total volume by the desired transit time for the liquid. For instance, if a 500-gallon pond requires full circulation once every hour, you should choose a pump with a 500 GPH minimum rated flow rate (gallon per hour).

Although pumps can function in a wide range of temperatures, if you are working with liquids that are hotter than 200°F, make sure the pump is rated for the highest liquid temperature you will be pumping.

Vapor pressure: The force per unit area that a fluid exerts when changing from a liquid to a vapor is known as vapor pressure, and it can be used to reduce the risk of cavitation by making sure the pump is rated for it.

Choosing a Pump from a Variety of Types

You can start comparing your options for pumps once you know the materials they must handle and the capabilities they need. The most typical pump designs and operating principles available today are listed below:

Centrifugal pumps: A centrifugal pump draws fluid into one or more impellers, such as a paddle wheel or propeller, to maintain a steady flow of a large volume of fluid at high speed. It can be used to pump a variety of low viscosity liquids, including those containing solid components like wastewater, and is one of the most popular pumping systems. A wide range of industries, including agriculture, water utilities, industry, power generation, petroleum, mining, and more, use centrifugal pumps.

Diaphragm pumps: Also called membrane pumps, a diaphragm pump is a device that moves fluid by a series of diaphragms moving back and forth. In a cycle, fluid is forced out of one chamber as it enters the other. These pumps are useful for pumping liquids with high solid content or high viscosity, such as chemicals, paints, or syrups, because there are no moving parts within the diaphragm chambers themselves.

Pumps that circulate fluids within a system are used instead of pumps that move liquid from one location to another. In order to ensure that the hot water is evenly distributed with the incoming cold water and to maintain a constant temperature, circulating pumps are frequently used in water heating systems. A circulating pump can also be used to evenly distribute chemicals that have been mixed into a container or to move water around a pond to oxygenate the water.

Pumps for moving oil, fuel, and other materials from one container to another, such as transferring fuel from a tank into large machinery, are known as fuel and oil transfer pumps. Oil transfer pumps are made for use with high viscosity fluids and are toughly constructed for higher flow rates.

Pumps for chemicals: Chemical pumps are made specifically for the creation, use, and disposal of chemicals. They are constructed of corrosion-resistant materials like glass, rubber, plastic, rubberized steel, titanium, and stainless steel. Use a pump made specifically for the chemical you want to pump because different chemicals have different corrosive effects on materials.

Drum pumps: These pumps are designed to help you suction out fluids from drums, barrels, pails, and totes to reduce the risk of spills when pouring the container or to draw fluids out of a heavy container. Hand-powered pumps are useful for low-volume or remote pumping applications where electricity is not available, whereas electric-powered pumps are useful for tasks requiring high volume transfer. A pneumatic pump that runs on compressed air is a good choice if you need higher flow rates than a hand-powered pump and more precise flow control than an electric drum pump without electricity.

Sump pumps are set off automatically once the water level in the sump pit gets to a predetermined height. A homeowner can calibrate the pump to start at any depth they wish by adjusting the float device of the sump pump.

Water runoff and/ or seeping water is collected inside the sum pit. As the water gathers, a float rises as the water level rises. The float has control of an on/ off switch for the pump. Once the float rises to a predetermined height, the pump turns on. The pump continues to function until the float falls low enough to disconnect the switch. The pump is inactive once more until the water level increases again.

Types of Sump Pump Floats

Different types of floats are used by different types of sump pumps. Pedestal pumps will typically have a bulb type float connected to a metal rod that turns on the pump motor’s switch. Other types of pumps utilize floats attached to arms that will raise and lower as the water level rises and lowers. A tethered float is a float that is attached to the pump utilizing a tethering mechanism.

Old Sump Pump Float Working Principle

When the water level rises, the float will rise too. As the float rises the tether steadily releases. The tether is predetermined to start the pump when a specific amount of tether gets released. When the water levels lower, the tether becomes loose and the float falls back to its starting position.

New Sump Pump Float Working Principle

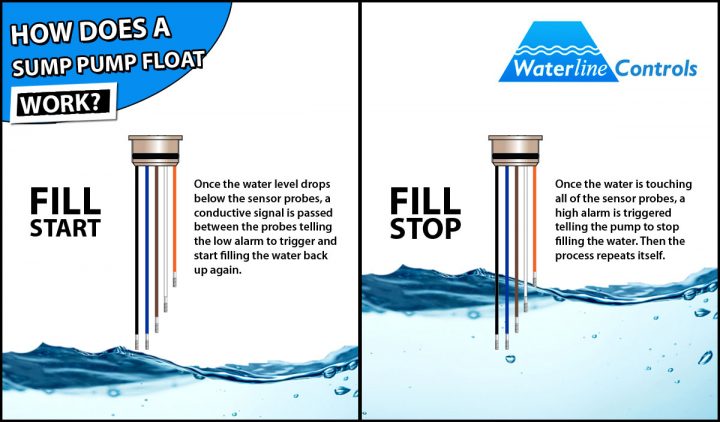

Float switches and water level controls typically start out open, meaning there are no alarms that are required to be activated since the water level is at its lowest.

- When the cooling tower stops using the water for its industrial operations, the water level starts to rise. No alarms have been activated up to this point.

- When the water level reaches the probes, a signal is transferred between the probes informing the high alarm to activate.

- When the high alarm is activated it can be programmed to tell the fill to stop filling up the water.

- Finally, when the water reached the predetermined limit, the fill stop kicks in and the process starts all over again.

With correct maintenance, your cooling tower float switches could last for years of operating. A lot of float switch failures typically occur due to degrading, wearing out, or fouling. Cooling tower coatings can safeguard the storage tanks, but what is safeguarding the float switches? Our water level controls can replace your old float switches once and for all and won’t degrade, wear out, or foul, because of any water quality.

Why Choose Water Line Controls

All of our water level controls and water level control systems are assembled right here in the U.S.A. where we monitor every step of the process.