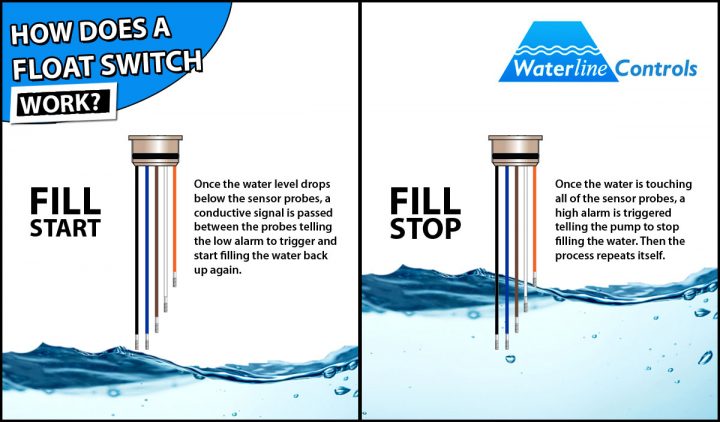

Float Switch Working Principles

A float switch is a simple device used to detect the level of liquid within a tank or system and control equipment like pumps, alarms, or valves. Here’s how it works:

⚙️ Float Switch Working Principles

🔹 1. Basic Concept

A float switch relies on a buoyant object (the float) that moves up or down with the liquid level. When the float reaches a certain height, it triggers a switch—either opening or closing an electrical circuit.

🧰 Types of Float Switches & How They Work

🔸 Mechanical Float Switch

-

How it works: A float is physically connected to a mechanical switch.

-

Action: As the float rises or falls with the liquid, it moves a lever or tilts, toggling a microswitch inside the housing.

-

Use case: Sump pumps, water tanks, bilge alarms.

🔸 Magnetic Reed Float Switch

-

How it works: The float contains a magnet, and the switch inside the stem is a reed switch (a magnetically operated contact).

-

Action: When the float rises or lowers, the magnet moves near the reed switch, causing it to open or close.

-

Use case: Industrial liquid level sensors, HVAC systems.

🔸 Mercury Tilt Switch (older design)

-

How it works: The float tilts and shifts a small sealed capsule containing mercury.

-

Action: The mercury makes or breaks contact as it moves inside the capsule.

-

Use case: Less common now due to mercury hazards.

🔌 Wiring Logic (Normally Open vs. Normally Closed)

-

NO (Normally Open): The circuit is open until the float rises or falls to trigger it—then it closes and sends power.

-

NC (Normally Closed): The circuit is closed until the float changes position—then it opens.

💡 Typical Applications

| Application | Float Switch Role |

|---|---|

| Water pumps | Turns pump on/off when water hits set level |

| Tank overfill protection | Triggers alarm or shutoff if level too high |

| Aquarium sump systems | Auto top-off to maintain water level |

| Industrial tanks | Monitors chemical or fluid levels |

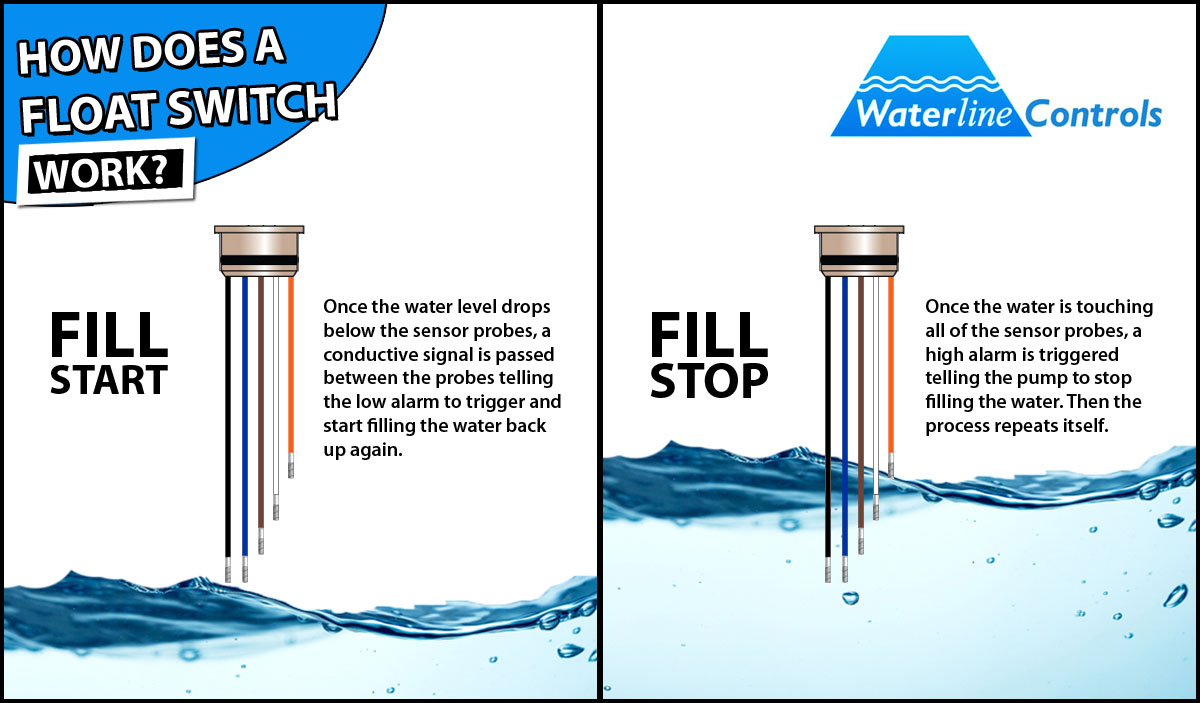

Why Choose Water Line Controls

All of our water level controls and water level control systems are assembled right here in the U.S.A. where we monitor every step of the process. The are many reasons to choose Waterline Controls™ for all of your float switch and water level controller needs include:

SIMPLE DESIGN

No moving parts or mechanical floats to break or rust!

BEST TECH SUPPORT

No runaround, no guessing, no stupid answers. You’ll talk to the guy who’s been designing and installing these units for over 20 years.

BUILT TO LAST

Makes it easy to integrate with existing Building Management Systems and has an expected useful life of 15 years.

TOUCH TO TEST

One push of the button starts a complete validation cycle to ensure all systems are working properly.

RELIABLE & ACCURATE

Will not foul, plate, or deteriorate regardless of water quality.