INSTALLATION VERIFICATION

Verify the installation was done correctly and completely before running through Troubleshooting steps.

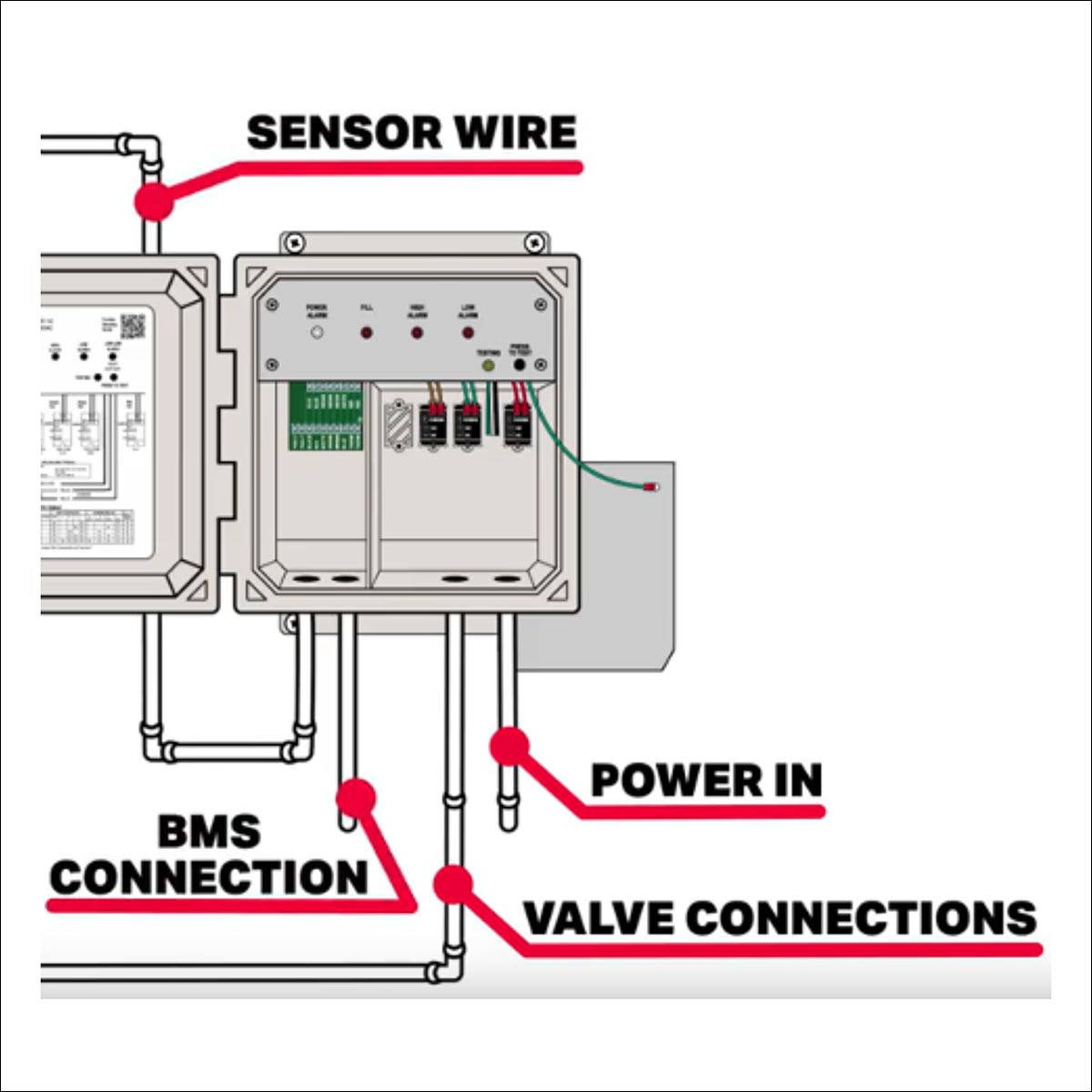

Sensor Cable Installation

- Do not coil sensor cable. This could lead to signal interference issues.

- CAUTION: Sensor cable near high voltage wires or conduit will produce false signals.

- Sensor cable should be in a separate grounded conduit away from high voltage wires or VFDs.

- Maintain at least 3” spacing between the sensor cable and high voltage lines.

- Do NOT run the sensor cable in the same conduit with high voltage lines.

- When crossing high voltage lines, cross them perpendicularly.

- Do NOT coil excess sensor cable. Doing so could generate ambient electronic noise like an antenna.

- Leave enough slack in the sensor cable so the sensor can be removed from the tank. Leave about 2 times the length of the longest rod. For example, if the longest rod is 17”, then leave about 34” of cable slack.

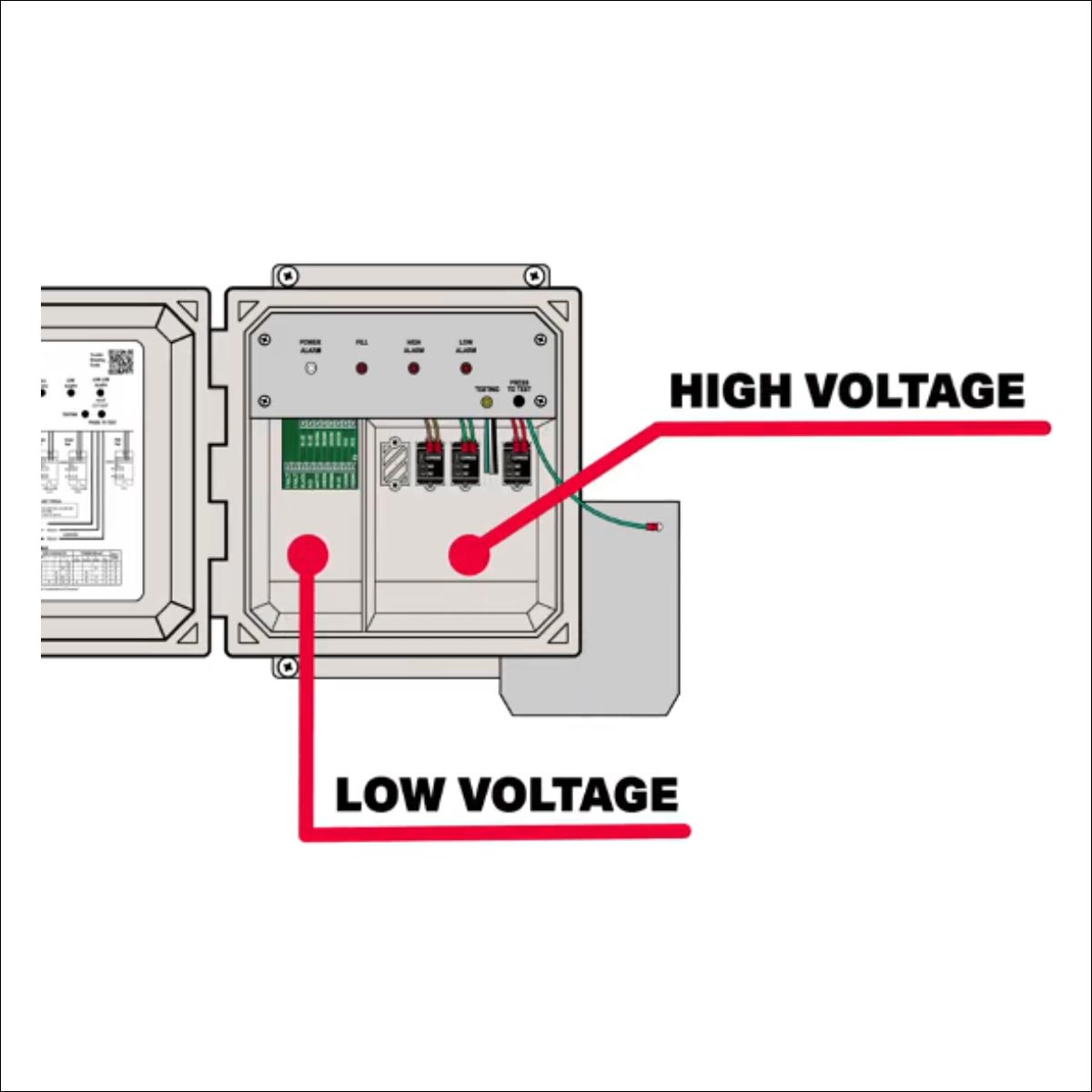

- Install sensor cable in the low voltage section (left side) of the control panel.

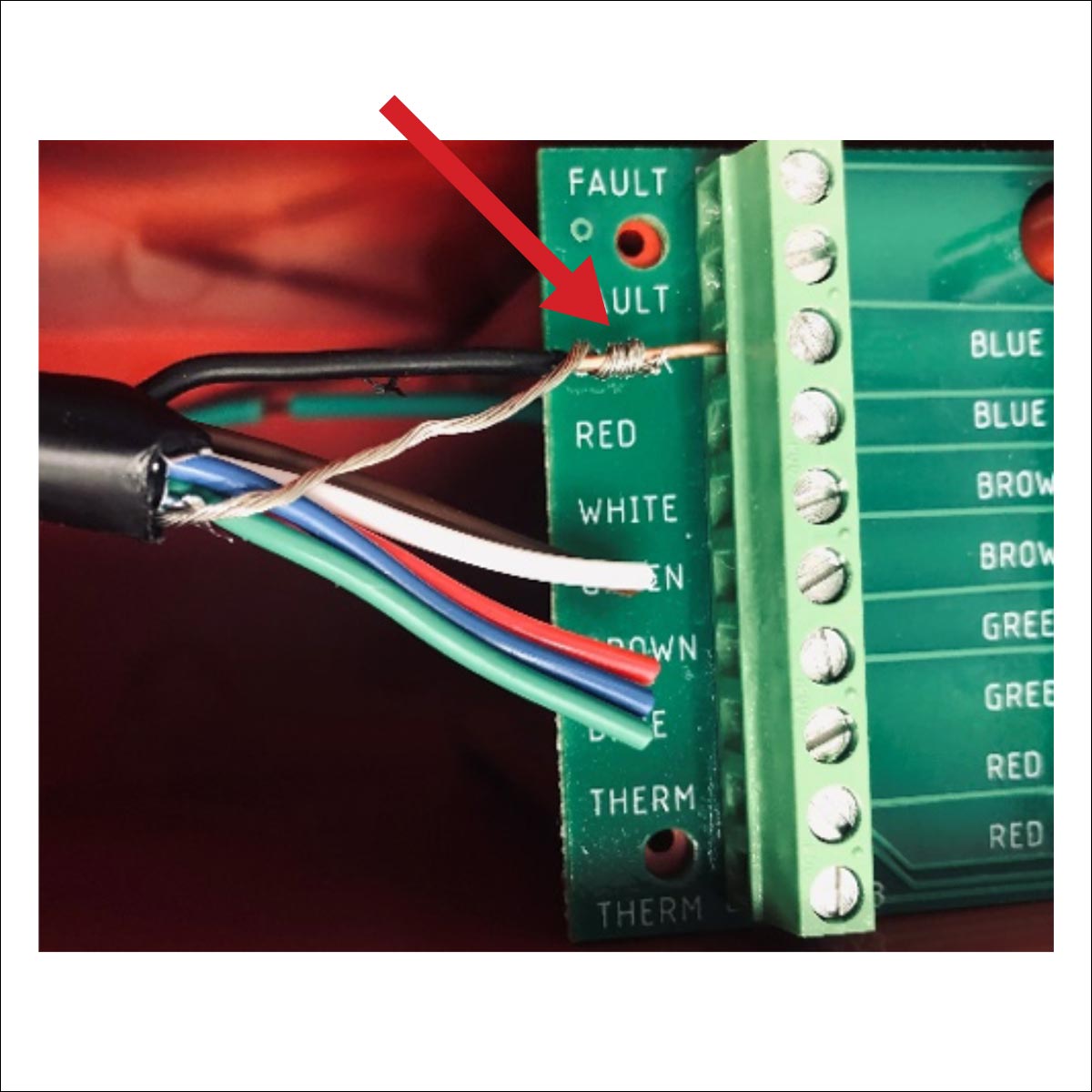

- Connect the sensor cable shield wire to the Black sensor wire.

PROUDLY MADE IN THE U.S.A.

All of our liquid level controls and liquid level sensors are assembled right here in the U.S.A.

where we monitor every step of the process.

NOT SURE WHAT YOU NEED? JUST CALL BECAUSE WE’RE HERE TO HELP! 480-905-1892

We offer products comparable to the products offered by the above companies. See our website pages for further information on the products. The tradenames and trademarks in this page are owned by their respective companies or are the same name as the company. They are mentioned for comparison purposes only. They are in no way affiliated with System Dynamics, Inc or WaterLine Controls.