ULTRASONIC WATER LEVEL SENSOR / TRANSMITTER

ULTRASONIC WATER LEVEL SENSOR / TRANSMITTER

NON CONTACTING MEASUREMENTS, CONTINUOUS WATER LEVEL DETECTION, AND SUITABLE FOR LIQUID AND SOME SOLIDS!

If you are searching for “Ultrasonic Water Level Sensors“, “Ultrasonic Level Sensor“, “Ultrasonic Level Detector“, “Ultrasonic Level Sensor 4-20ma” or “Ultrasonic Level Transmitter“, WaterLevelControls.Com can help! The WLC Ultrasonic Sensor is a cost-effective and reliable solution for volume, level and open channel flow measurement. Our ultrasonic level sensors work in storage tanks, buffer tanks, open channel flow and buffer tanks.

CALL US FOR PRODUCT ORDERS 1-866-243-2505 OR 1-480-629-8223 NON-US!

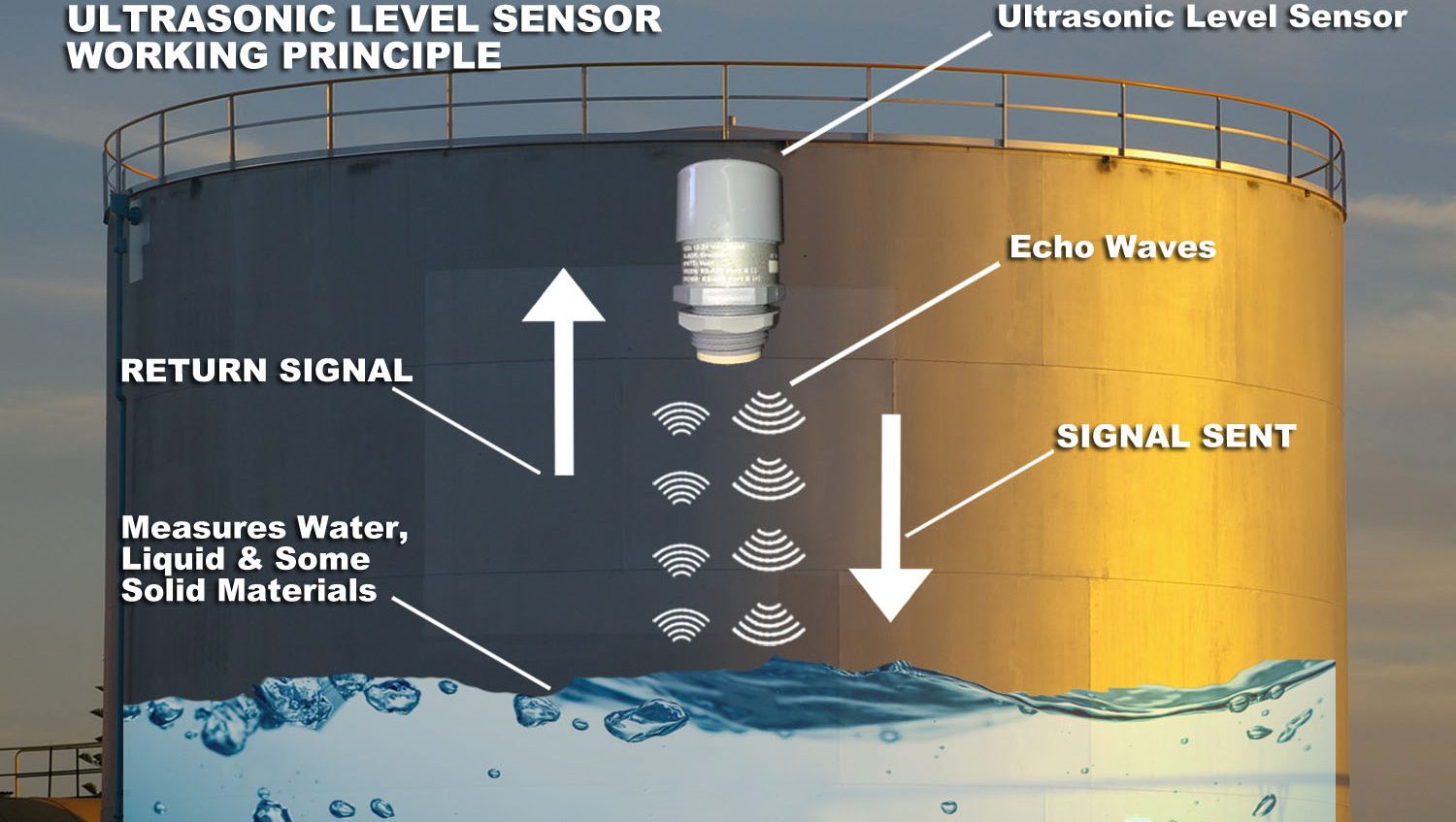

ULTRASONIC WATER LEVEL SENSOR / TRANSMITTER WORKING PRINCIPLE

This ultrasonic sensor is IP65 and is made in PVC. Ultrasonic Sensors use high frequency ultrasonic waves to detect the levels of any medium liquid or solid. This sensor/transmitter is mounted at the top of a tank and aimed downward.

It transmits waves and measures the time it takes to receive the return signal back from the water to the sensor. The measured time is then used to output a level in terms of a precise voltage from 0-10 volts.

ULTRASONIC WATER LEVEL SENSOR WORKING PRINCIPLE

For those searching for “ultrasonic level transmitter working principle” or”ultrasonic water level sensor working principle”, the diagram above and explanation below should help you understand more about these sensors. The ultrasonic level sensor/transmitter, once installed in your tank, work by sending a high frequency signal to the water/liquid/solid material or media and measures the time it takes for the signal to reflect back to the PLC (10ft away or 15ft away etc). That signal is sent back with either a 0-10 volt signal or a 4-20 miliamp (4-20ma is the most common). When you pair one of these sensors with our PLC control panels it allows the user to set automatic activation point for devices such valves, pumps and alarms etc.

ULTRASONIC LEVEL SENSOR ADVANTAGES AND DISADVANTAGES

ADVANTAGES

- Simple installation and operation

- No moving parts

- Non-contacting measurement

- Continuous water level detection

- Can be used some non-liquid materials/media

- Suitable for liquid and some solids

- High accuracy & sensitivity

DISADVANTAGES

- Turbulence in water can potential cause temporary inaccurate readings (not common)

- Costs a little more than other types of water level sensors (more circuitry involved, high frequency transducer, etc)

- May be difficult to sense levels at long range (most applications require only a short range)

- Not appropriate for materials or tanks that can hamper the sensor’s received echo (odd shaped tanks, divider plates can throw off the signal, etc)

PROUDLY MADE IN THE U.S.A.

All of our liquid level controls and liquid level sensors are assembled right here in the U.S.A.

where we monitor every step of the process.

NOT SURE WHAT YOU NEED? JUST CALL BECAUSE WE’RE HERE TO HELP! 480-905-1892

We offer products comparable to the products offered by the above companies. See our website pages for further information on the products. The tradenames and trademarks in this page are owned by their respective companies or are the same name as the company. They are mentioned for comparison purposes only. They are in no way affiliated with System Dynamics, Inc or WaterLine Controls.